Lab Mixing & Milling for Scale-Up

At Burke Industries, we offer small-scale lab mixing and milling to minimize the cost of your product development cycle. With a wide array of on-hand elastomers and chemicals, we can quickly develop mixing and milling cycles in preparation for development and scale-up of your recipes.

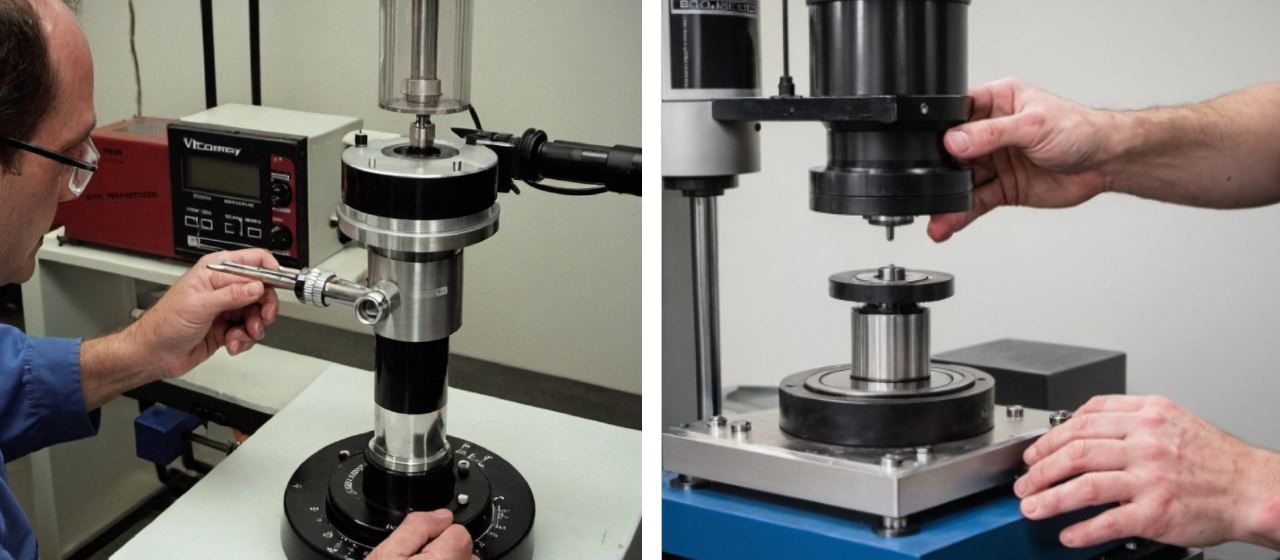

MDR, ODR, Mooney Viscosity

We feature a wide array of rheology tests to ensure the characterization of your rubber meets your processing needs. We also ensure your rubber will arrive meeting your scorch safety and viscosity specs through a variety of testing methods and experience in interpreting the performance of your product.

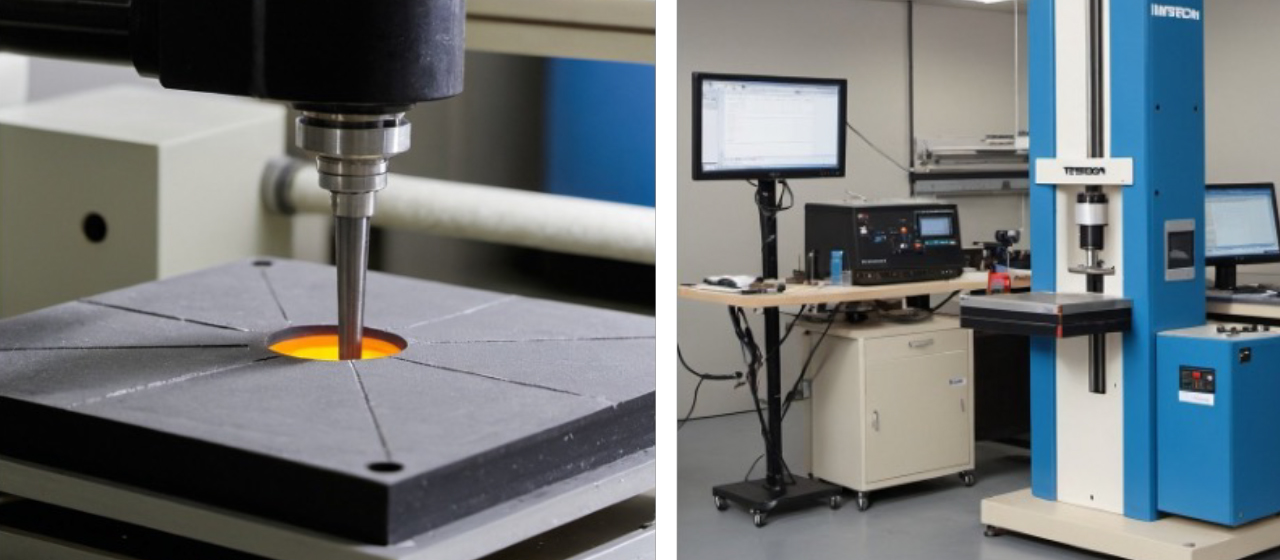

Tensile, Stress & Strain

Our testing lab will ensure your rubber meets or exceeds all the mechanical demands of your product. Whether it’s stress and strain, tensile strength, or more sophisticated methods for Possoin’s ratio, we are prepared to work with you to ensure your material will survive the rigors of its lifecycle.

Hardness Testing

Hardness plays a critical role in the lifecycle of rubber, so we will be right there to support you in ensuring your cured parts needs are satisfied. Our lab can test for both Shore A and Shore D durometers that meet a variety of MIL and ASTM requirements.

Flow & Dimensional Stability

Need to know how your rubber will flow during molding or shrinkage rate? Our lab features a variety of compression molding solutions to determine how your product will respond to heating and cooling cycles as it stands the test of time during operation.

Dielectric Properties

No matter the application, we have a test. If your rubber needs to meet specific conductivity requirements, we are prepared to examine your rubber to ensure the flow stays in the conductor and not your rubber.

High-Resolution Scanning/Microscopy

Need a deeper dive into the surface details of your mix? We do that, too. From cross-sectional imagery to high-resolution surface detail, we can give you the confidence needed that your product was made right.

ASTM, MIL-SPEC, Others

Don’t see a specific test you need performed? That’s not a problem for Burke Industries. We have relationships with countless industry partners who help complete your testing requirements and will be happy to ensure your product satisfies customer requirements.

SUBMIT YOUR REQUEST

Core Technical Testing at Burke